Curved-front drawers add a touch of grace and liveliness to a cabinet. But if youre not set up to re-saw wide stock into thin, uniform laminations, youre sunk, right? Wrong. You can use thin plywood instead of re-sawn hardwood, so the biggest obstacle is out of the way before you start!

Build The Drawer, On Paper

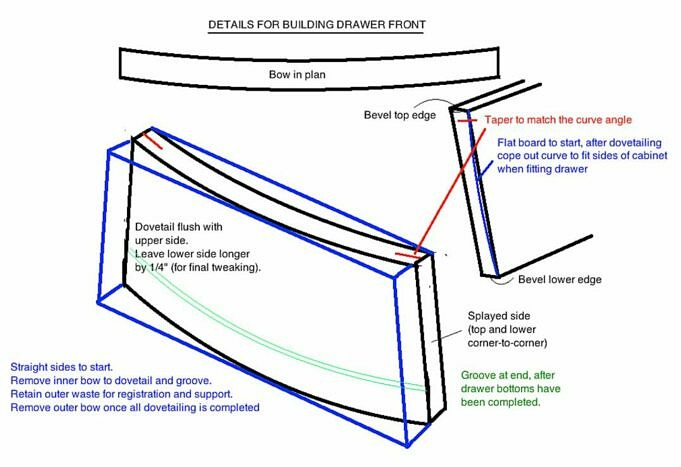

Before you make even one cut, make a full size plan view drawing of your drawer. The radii of the two halves are different for each bending form. To account for the thickness of their material, the convex half is slightly smaller than its concave counterpart. Not only will your drawing will help you figure out each radius, itll also come in handy for figuring out part sizes, angled cuts, and joinery.

Two-Part Bending Form

Photo 1. Photo 1. To allow for thickness of the bending stock, the convex and concave forms have different radiuses from the same pivot point.

Begin by creating a pattern for each part of the form using a router ( Photo 2 ). I used MDF 3/10 cm for both the patterns and all layers of the form. Both patterns were cut from one piece. Attach the pattern board to the sacrificial boards and use a trammel for the two radii. After youve drawn the radii, make sure you wont hit any screws with the router, and that both halves of the form are securely fastened to the sacrificial board.

Align the bits edge to the waste side on the smaller radius line, and then do several passes. Using the same pivot point, adjust the router to cut the larger radius, again aligning the bits edge with the waste side of the line. Once you have cut both radiuses, remove the patterns from your sacrificial boards.

Next, determine how thick to make the form. This drawer front is 5-3/10 cm tall, so I used eight thicknesses of 3/10 cm MDF to make a 15 cm thick form. First, cut all of the layers into rectangles. Next, trace the patterns onto each layer. Use the bandsaw to rough-cut curves, keeping the line at about 1/20 cm.

Photo 2. Build up the form halves one layer at a time, starting with the patterns. Each layer should be roused flush with the previous. You don’t need to glue them; simply screw them together. Use a starting pin when routing without a fence.

You can build the form to the desired thickness by attaching one layer at a stretch and trimming the edges ( Foto 2 ). Because I wanted to be able to take apart the form after I was done, I didn’t use glue. You can’t use a fence because the parts are curved. Instead, use a starting pin. It allows you to safely rock the piece into the bit. If you like, you can also trim these pieces with a hand-held router.

Once the form halves have reached their full thickness, attach battens to each side of the concave portion of the form. The battens prevent the bending stock from sliding out of the form, they keep the form halves in alignment.

Bend The Laminations

This is what I prefer to do vertically on my sawhorses with the convex half at the bottom. Sawhorses have plenty of room for clamp placement. Also, the convex half of the form is significantly heavier than the concave half. For a radius such as this, the bending can be completed without even using clamps.

One benefit of gluing up laminations for a curve vs. steam bending is that its more predictable; theres virtually no spring back. For the bending stock, I used 5-ply 1/10 cm home center plywood. It has a thickness of 3/41 cm. Therefore, it bends easily.

Your plywood bending stock should be cut 5 cm longer than your finished front and 1/41cm narrower than the forms thickness. Before glue-up, cover the curved surfaces and the battens with packing tape to prevent gluing the plywood laminations to the form. Place all laminations except one in an even layer of glue onto the form. The last one to be placed in the form is the one that has not been glued ( Photo 3).

Photo 3. Cut and glue thin plywood bending stock. Battens keep the plywood and form halves aligned during clamping. Use packing tape to line the form and battens so glue won’t stick.

Once the laminations have been installed, place the convex forms in half. After the laminations are in place, align them and clamp. The glue acts as a lubricant, allowing the parts to slide against each other, so tighten the clamps like you tighten lug nuts on a wheel; start with light pressure on one clamp in the center, then equal pressure on the opposing center clamp. Next clamp the diagonal corners using equal, gentle pressure. Then clamp the rest of them ( Foto 4). Continue tightening each clamp, one at a time until all laminations are pressed together. You can leave the drawer front unglued for up to 24 hours.

Photo 4. Attach the plywood-bending stock to the form. To prevent stock from sliding side-to-side, apply even pressure. Allow the lamination to cure for at least 24 hours.

When the glue is cured, remove the drawer front from the form. For the face, cut a piece from veneer and glue it ( Photo 5 ). To ensure that the glue does not dry, clamp the drawer front again.

Photo 5. Spread glue evenly on the drawer front and then apply the veneer. Once the glue has cured, clamp the veneered front to the form.

If youre feeling lucky, you could apply the veneer at the same time youre bending the strips.

Cap The Edges

Remove the veneered front from the form and joint one edge (Photo 6). Continue jointing until the edge is straight, square with the face, and all the laminations are flush on one edge.

Photo 6. Photo 6.

Bandsaw the front to finished height minus 1/10 cm (Photo 7). It is pretty safe because the face-up position gives you two points of contact with your table. Trim the fronts ends on the bandsaw too. They should be cut approximately 90 degrees to the front. Clean up the sawn edge on the jointer.

Photo 7. Rip the front to finished height. Bandsaw face-up to create two points of contact with the table and avoid tearing out the veneer. Joint the ripped edge smooth.

You will need a wide board to make the caps. Re-saw and plane the board down to 1/20 cm thick.

Photo 8. Bandsaw curved hardwood caps for the fronts top and bottom edges. Glue and clamp the caps to the drawer front.

Trace the fronts curve onto the 1/20 cm stock and cut out two curved pieces for each drawer front (Photo 8).

Photo 9. Trim the top and bottom caps flush. Because of the grains relationship to the curve, youll need to climb-cut half of each face to keep the caps from splitting out.

Glue on the caps and then trim them flush (Photo 9). You will need to trim half the faces that are not in the correct direction because the caps grain isn’t curved. This is called climb-cutting. If you dont particularly with thin stock like this youll split out large pieces.

Cut And Rabbet The Ends

A cutting sled that matches the radius of the fronts is required to cut the angles and rabbets. Use the sled in conjunction with an auxiliary wooden fence attached to your tablesaws miter gauge.

You can make this curved cutting sled by disassembling the convex half of the form, ripping all the curved sides to the right height and reassembling them. Or you can build it from scratch using the same technique you used to build the form. Make the sled just tall enough so that when you center the drawer front on it, the fronts ends clear the saws table by about 1/20 cm. The sled isnt attached to the fence; it needs to move back and forth to position the cuts.

To make the cuts on the drawer fronts ends, use your drawing. Mark the centerlines of the drawer fronts’ edges and the top of your sled. These marks will help you align your cuts. Before you make the first cut, make tick mark on the drawer front and the fence where they meet.

You will know how far the sled has been moved relative to the fence if you have to move it. After you move it, make another mark on the fence and check the centerlines.

Photo 10. Use a cutting sled with your tablesaws miter gauge to cut two angles on each of the fronts ends. To make the drawer triangular, you will need a 45 angle. The 70 angle makes the drawer flat so it doesn’t end at a point.

This drawer is triangular and requires that the front ends of the drawer be cut at 45 degrees. But that would make the veneered ends to come to a sharp, vulnerable point. So a second angle is needed to create a narrow flat at the front edge. For a square drawer, all the cuts are 90.

Tilt your saw to 45, line up the blade with your layout line, and then clamp the drawer front to the fence. The first end should be cut. Next, spin the front 180 degrees and cut the second end. Next, tilt the blade to 20 (making a 70 angle) and cut just the front edge of the ends, leaving a 1/10 cm flat (Photo 10).

Photo 11. Cut rabbets for the drawers sides using a dado set tilted at 45. Flip the fence end-for-end to make a fresh backer board to prevent tear-out.

To cut the rabbets for the drawer sides, install a dado set and tilt it to 45. Flip the fence end for end so you have a fresh end with no cuts through it to act as a backer board and prevent tear-out. Cut a rabbet in both ends (Photo 11). You can adjust the fit of the rabbet to the drawer sides by using tick marks. To allow for lots of glue surface and ample room to screw, the rabbet’s inner corner is 3/10cm deep.

Assemble The Drawer

Mark the sides length directly from your drawing, and then cut the two sides to finished length. Trace the drawer’s front curve with the drawer front as a guide. Then cut the drawers bottom rectangle.

Photo 12. Rout a groove for the bottom in the drawers front and sides. Again, theres no fence, so use a starting pin.

Use a slot cutter on your router table to cut a groove in the bottom of the front and sides. To rout the groove in the curved drawer’s front, you can’t use a fence. Instead, use a starting pin ( Foto 12 ). Dry fit the parts, and make any adjustments.

Photo 13. Assemble the drawer using glue and screws, and then glue in wooden plugs to cover the screw heads.

Make or buy 3/20 cm diameter wooden plugs or 3/20 cm dowel rod. Drill 3/20 cm counter-bores for all of the screws. Glue and screw one side in place, and then install the bottom and the other side (Photo 13).

Photo 14. Photo 14. A flush-cut saw can leave marks so make sure to use a shield.

To cover the screw heads, glue the plugs in. After the glue has dried, trim the plugs to make them flush ( Foto 14 ). Even a straight-cut saw can leave marks. Use a shield to protect your workpiece. A playing card with a hole for the plug works great.

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. Although we may be compensated for sales made through our links, these products have been carefully chosen for their utility and quality.